Stereo Doppler Microwave sensor in Explosion-proof housing

Approved by the USAF for Protection Level 1 Nuclear & Below

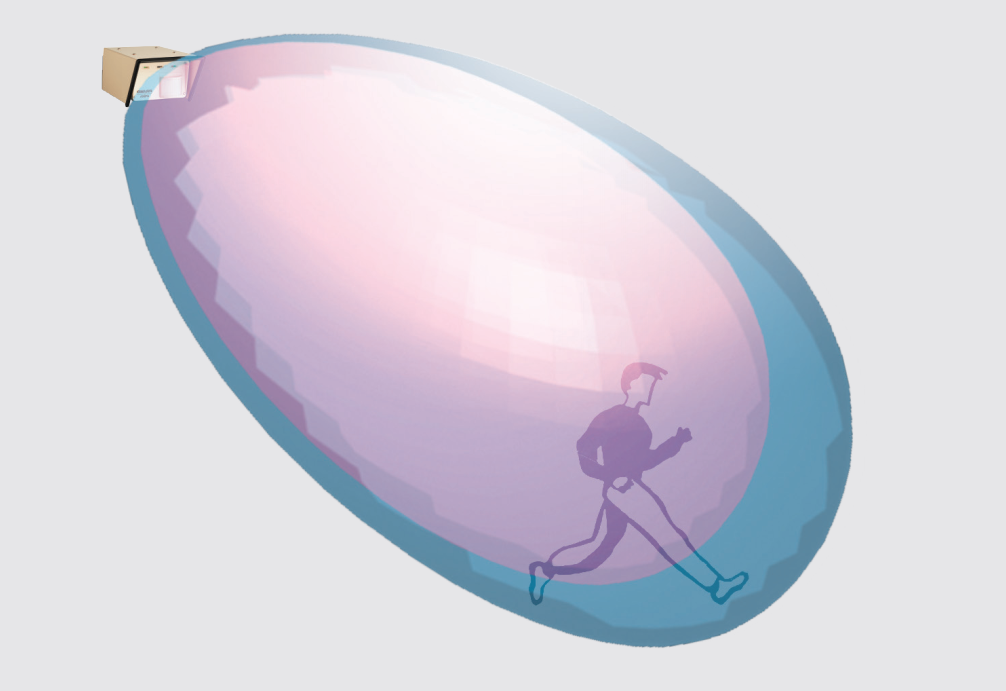

COVERAGE: VOLUMETRIC SENSOR

SDI-77XL2-EX: H 40°, V 40°, 100ft. x 40 ft. (30m x 12m)

RELIABILITY : Ideal for highly sensitive sites and applications – conforms to various hazardous site Class requirements – see below

PERFORMANCE : High performance digital signal processing and adaptive circuitry facilitates high reliability and performance

INNOVATION : PROTECH’s unique proprietary “Stereo Doppler” technology enables false-alarm-free performance over a wide variety of applications

Overview

Approved by the USAF for Protection Level 1 Nuclear & Below

The PIRAMID SDI-77XL2-EX (Stereo Doppler Motion Detection Sensor) was developed to protect hazardous sites with the presence of flammable gases or vapors, combustible dusts or easily ignitable fibers or particulates. The SDI-77XL2-EX electronic assembly is configured to be easily inserted into a special explosion-proof enclosure. The sensor is suitable for application in Hazardous Locations under the following classifications:

- Class I, Div. 1 & 2, Groups C,D

- Class II, Div. 1 & 2, Groups EFG

- Class III

- NEMA 4, 7BCD, (EFG)

Also available for applications outside North America is PIRAMID ATEX, compliant with ATEX Directive 2014/34/UE. PIRAMID ATEX is suitable for sensitive sites classed Zone 1 and 2 for flammable gases and Zone 21 and 22 for combustible dusts.

The Stereo Doppler technology features two receiving channels with the ability to eliminate vibration and randomly moving objects as sources of unwanted alarms.

The PIRAMID EX is suitable for installation at petroleum refineries, chemical and petrochemical plants, storage areas and other processing facilities where hazardous substances are handled or stored. Whether your application is inside or outside Protech has the explosion proof sensor for the job.

For indoor and outdoor applications there is specialized software written for each EX sensor.

SDI-77XL2-EXIND has a higher sensitivity for movement and has an optional PCB for fluorescent light noise filtering.

SDI-77XL2-EXOUT has software that will compensate for heavy rains and a selection for immunity to birds and small animals.

| Input voltage | 10.5 to 28 Vdc (Also available in 24 VAC) |

| Consumption | 100 mA at 12 Vdc (LEDs OFF) |

| RF power density | 120 µW/cm² maximum in front of the device |

| Factory setting frequency | USA – 10.525 GHz, International - 10.587 GHz / 9.90 GHz / 9.47 GHz |

| Operating temperature | -40°F to 158°F (-40°C to +70°C ) |

| Relative humidity | 0 to 100% |

| Relay contact capacity | 100 mA / 50 V |

| Housing dimensions (mm) | 330,2 (L) x 317,5 (W) x 238,8 (H) |

| Housing dimensions (inches) | 13.0 (L) x 12.5 (W) x 9.4” (H) |

| Package dimensions (mm) | 355,6 (L) x 355,6 (W) x 254 (H) |

| Package dimensions (inches) | 14 (L) x 14 (W) x 10” (H) |

| Weight | 34 lbs. 10 oz (17.5 kg), Shipping wt. 42 lbs. (19 kg) |

| IP rating | IP66 compliant with EN 60529 and IEC 60529 Mechanical resistance IK10 compliant with EN 50102 |

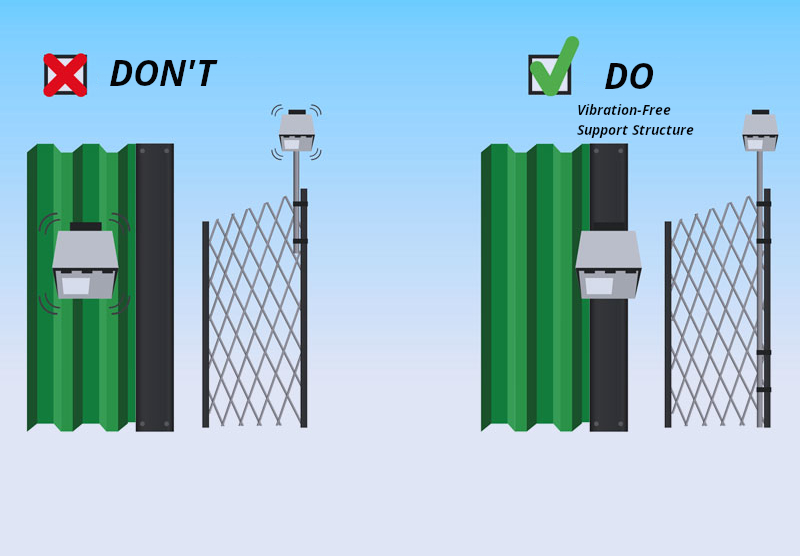

Must be installed on a solid wall, pillar or pole free from extreme vibration.

If installed on a building with a metal surface, support must be vibration-resistant.

Aim the sensor downward so that its coverage stops on the ground in the required protection area. Please note that the sensor can detect large objects such as vehicles (cars, buses, etc.) at a distance of greater than 500 ft. (150 meters).

When mounting on oil platforms, aim the sensor away from moving water.

The SDI-77XL2-EX Model of Stereo Doppler Motion Detection Sensor was developed to protect Hazardous Locations due to the presence of flammable gasses or vapors, combustible dusts or easily ignitable fibers or particulates.

The SDI-77XL2-EX electronic assembly is configured to be easily inserted into a special explosion-proof enclosure. The unit is suitable for applications in Hazardous Locations under the following classifications:

- Class I, Div. 1 & 2, Groups C,D

- Class II, Div. 1 & 2, Groups E,F,G

- Class III

- NEMA 4, 7BCD, 9EFG

The unit is suitable for installations at petroleum refineries, chemical and petrochemical plants, storage areas and other processing facilities where hazardous substances are handled or stored. Easily ignitable fibers and particulates include rayon, cotton (including cotton linters and cotton waste), sisal or henequen, istle, jute, hemp, tow, cocoa fiber, oakum, baled waste kapok, Spanish moss, excelsior, and other materials of similar nature.

The proprietary microwave design using stereo Doppler, detects the volumetric changes created by an object in the field of detection. Special filtering is included to enable exceptional immunity to birds and small animals.

- Stereo Doppler Microwave Detector: Two receiving channels with the ability to eliminate vibration and periodically moving objects as sources of false alarms.

- Microprocessor controlled: Proprietary integrated circuit design that provides enhanced digital signal processing for microwave sensor.

- Stereo Doppler Supervision: A component or power failure will cause the sensor to lock-in alarm.

- Digital Range Control: Ten-position digital switch adjusts the overall size of the sensor’s detection area (to its maximum range).

- Digital Sensitivity Control: Ten-position digital switch adjusts the amount of movement required to initiate an alarm condition.

- Enhanced Bird/Animal Immunity Control: Two-position switch adjusts the sensor’s immunity to birds and small animals.

- Tamper: Housing tamper with terminal connection.

- Solid State Relay: User selectable form C relay output. A Solid State relay is flexible, silent, and more reliable than an electromechanical relay.

- Walk-Test Sounder: Optional audible tester to assist in the walk-test and initial sensor set-up. The XL-Minisounder greatly simplifies the installation as it enables walk-testing and adjustment by a single installer.